TS55-1800

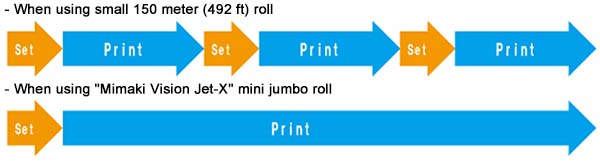

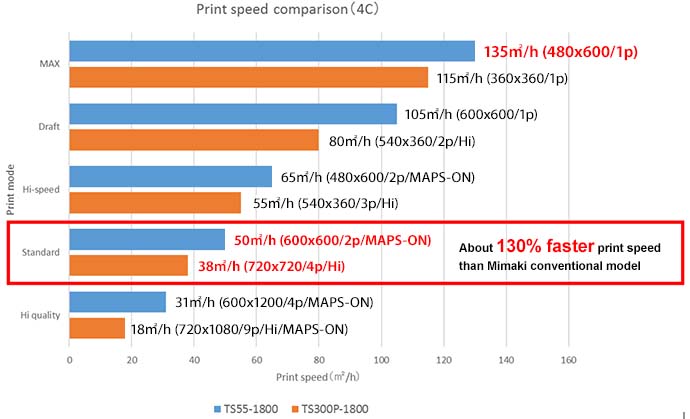

The TS55-1800 is a dye-sublimation transfer paper model, offering new levels of quality and productivity for digital textile printing. This printer keeps running costs low with the mini jumbo roll and 10 kg ink supply units, which allows for unattended continuous printing. A maximum output of up to 1,506 SqFt/Hr can be achieved in four-color mode. New Sb610 inks, with fluorescent yellow and pink, provide enhanced resolvability to improve print production yields.

QUICK SPECIFICATIONS

480, 600, 1,200 dpi

Max Print Width76.3 inches (1,940 mm)

Max print speedMax: 1,506 SqFt (140 SqM)/Hr

Standard: 592 SqFt (55 SqM)/Hr

High quality: 333 SqFt (31 SqM)/Hr

99.2 lbs (45 kg)

Single-phase AC 100-120V/ AC200-240Vx1

Weight445.3 lbs. (202 kg)

Dimension (WxDxH)127.5 x 28 x 73.1 inches (3,240 x 713 x 1,857 mm)

Mini Jumbo Roll Unit

Mini Jumbo Roll Unit 10 kg Ink Supply Unit

10 kg Ink Supply Unit Extended Heater

Extended Heater

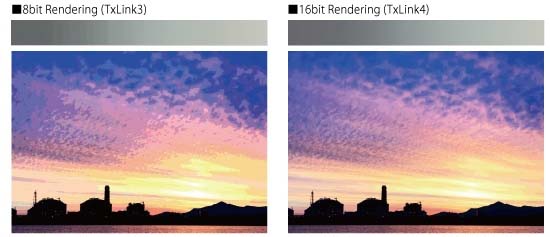

Light black ink enables stunning gray-scale expression.

Light black ink enables stunning gray-scale expression. Fluorescent inks enable unique expression.

Fluorescent inks enable unique expression.